- होम पेज

- कंपनी प्रोफाइल

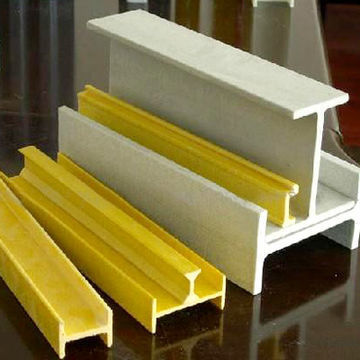

- हमारे उत्पाद

- संपर्क करें

FRP Pipe

75 आईएनआर/Meter

उत्पाद विवरण:

- एक्सेसरीज़ Flanges, Adapters, Joints Available

- टाइप करें

- फंक्शन Fluid Transport, Corrosion Resistance

- सतह की सामग्री FRP

- मटेरियल

- इनफ़िलिंग

- सतह की फिनिशिंग

- Click to view more

X

मूल्य और मात्रा

- मीटर/मीटर

- मीटर/मीटर

- 100

- ASTM, IS, BS

- Lightweight compared to metal pipes

- Bell and Spigot, Flanged, Threaded

- Up to 32 bar

- Excellent

- Chemical Resistant Liner

- Up to 12 meters or as required

- >25 years in standard conditions

- Matte/Smooth Finish

- -40°C to 120°C

- Non-Conductive, Electrically Insulated

- Easy to install, low maintenance

उत्पाद की विशेषताएं

- FRP

- Cylindrical, High Strength

- Flanges, Adapters, Joints Available

- 5 mm to 25 mm

- Green, Custom Colors Available

- 50 mm to 3000 mm Diameter

- Fluid Transport, Corrosion Resistance

- ASTM, IS, BS

- Lightweight compared to metal pipes

- Bell and Spigot, Flanged, Threaded

- Up to 32 bar

- Excellent

- Chemical Resistant Liner

- Up to 12 meters or as required

- >25 years in standard conditions

- Matte/Smooth Finish

- -40°C to 120°C

- Non-Conductive, Electrically Insulated

- Easy to install, low maintenance

व्यापार सूचना

- सूरत

- 2000 प्रति सप्ताह

- दिन

- नमूना लागत, शिपिंग और करों का भुगतान खरीदार द्वारा किया जाना है

- ऑल इंडिया

उत्पाद विवरण

FRP (Fiber Reinforced Plastic) pipes are lightweight, corrosion-resistant pipes made from a composite of fibers and resin. They are widely used in industries like chemical processing, water treatment, oil and gas, and marine applications due to their durability and resistance to harsh chemicals. FRP pipes are ideal for transporting corrosive fluids, wastewater, and industrial chemicals. Their high strength-to-weight ratio and low maintenance make them a preferred choice for infrastructure projects, including pipelines, sewage systems, and irrigation. FRP pipes offer long service life and excellent performance in demanding environments.

Superior Corrosion and Chemical Resistance

Constructed with a chemical-resistant liner, our FRP pipes are specifically built to handle aggressive fluids. Their robust material composition resists corrosion far better than traditional metal pipes, making them a reliable choice in water treatment, chemical processing, and sewage systems, especially where longevity and safety are paramount.

Customizable and Easy Installation

Available in sizes ranging from 50 mm to 3000 mm diameter and multiple thickness options, these pipes can be tailored for any application. Lightweight yet strong, they simplify installation, reduce handling costs, and are compatible with various joint types, including bell and spigot, flanged, and threaded connections.

FAQs of FRP Pipe:

Q: How do FRP pipes compare to metal pipes in terms of weight and installation?

A: FRP pipes are significantly lighter than metal pipes, making them easier to transport, handle, and install. This lightweight nature reduces labor and installation time, resulting in cost savings and quicker project completion.Q: What makes FRP pipes suitable for corrosive environments?

A: These pipes have an inner chemical-resistant liner and are manufactured from inert fiberglass-reinforced plastic, which together provide excellent protection against corrosion from chemicals, water, and sewage.Q: When should you choose FRP pipes for your project?

A: FRP pipes are ideal for applications requiring corrosion resistance, lightweight materials, and long service life. They are perfect for water supply, industrial fluid handling, chemical processing, and sewage systems, especially in environments with aggressive chemicals or high moisture.Q: Where can FRP pipes be installed, and what joint types are available?

A: FRP pipes can be installed both above and below ground in various environments, including industrial, municipal, and commercial settings. Joint options include bell and spigot, flanged, and threaded, allowing flexible integration with existing systems.Q: What benefits does the matte or smooth outer surface of FRP pipes provide?

A: A matte or smooth finish reduces friction, minimizes dirt buildup, and enhances flow efficiency. It also contributes to the pipes UV resistance and long-lasting appearance, even under harsh outdoor conditions.Q: How long do FRP pipes last, and what maintenance is required?

A: Under standard operating conditions, FRP pipes have a service life exceeding 25 years. They require minimal maintenance, thanks to their corrosion resistance and chemically inert construction, ensuring long-term reliability.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese